James Fisher Strainstall has devised a range of instrumentation and monitoring solutions for application on concrete bridges.

Our solutions can be applied at all stages in a bridge's lifespan for short, medium and long term monitoring in order to identify and manage defects.

A4 Hammersmith Flyover

Hidden defect: Pre-stressing wires / strands / anchorages

Problem: Breakages of post-tensioning tendons meant that residual strength testing was required to monitor the effect of failures on the structure.

Solution: JF Strainstall undertook programmes of in-situ stress measurement in the post-tensioned concrete structure. This was part of the assessment of the structure’s residual strength following well publicised breakages of post-tensioning tendons, as detected by acoustic emission monitoring. James Fisher Testing Services also set up instrumentation for monitoring the structure during re-stressing operations.

M56 Bowden View

Hidden defect: Missing / inadequate rebar / pre-stressing

Problem: Risk of sudden bridge collapse.

Solution: JF Strainstall ascertained the dead load condition within a segmental post-tensioned concrete bridge deck. A monitoring system was fitted to the bridge, including acoustic emission sensors to detect pre-stressing wire breaks. Strain and displacement sensors were employed to monitor potential crack development.

M8 Kingston Bridge complex

Hidden defect: Half joints

Problem: The renewal of approach viaducts required strength testing to be carried out on existing half joints.

Solution: As part of a renewal of approach viaducts, a test to destruction of a half joint was undertaken, with monitoring by JF Strainstall. This was used to provide information about any hidden strength and to give confidence about the likely condition of the dozens of other similar joints within the junction complex.

M6 Lodge Lane Viaduct and Besancon Bridge, Huddersfield

Hidden defect: Corrosion of embedded reinforcement

Problem: During resurfacing work, concerns were raised as to the condition of the exposed reinforced concrete decks.

Solution: JF Strainstall conducted extensive half-cell potential measurements across the full deck areas. Colour contour plotting of the results highlighted several areas where high levels of corrosion activity were evident. Laboratory testing of incremental concrete samples extracted from these areas showed significantly high chloride values, also indicating probable corrosion activity. Removal of the surface concrete confirmed the problem with several reinforcing bars showing major loss of steel section leading to a reduction in strength.

All chloride contaminated concrete was removed and additional or new reinforcement was installed prior to concreting and re-waterproofing.

Ribble Walton Bridge, Preston

Hidden defect: Concrete delamination and corroded reinforcement

Problem: General condition survey found large areas of delaminated concrete.

Solution: JF Strainstall completed a comprehensive tap hammer survey to determine the full extent of the problem. Where concrete fell away the underlying reinforcement was seen to exhibit heavy surface corrosion. A full suite of testing was then carried out, including; cover depth, half-cell potential, resistivity, chloride sampling and carbonation depth testing. The cause of the problem was determined to be carbonated concrete down to the depth of the reinforcement, where reduced alkalinity had led to corrosion of the bars and subsequent concrete breakdown. All affected concrete was removed, the bars were cleaned, and spray concrete repairs were applied.

Read article

Read article

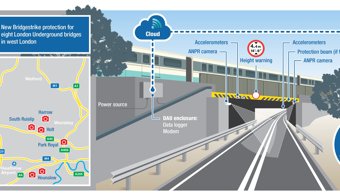

Detection of bridge impact

Read article

Bridgestrike installed two key bridges London underground

Read article

JF Strainstall delivers structural health monitoring project three Normandy bridges

Read article

JF Strainstall commissions structural health monitoring solution Queensferry crossing

Read article

Queensferry crossing meets internet things new bridge new rules

Read article

Bridge load testing eco city, Kuala Lumpur

Read article

Hidden bridge defects | Sub structure solutions

Read article