JF Strainstall has successfully designed and implemented structural health monitoring solutions in order to manage a wide range of hidden defects on metallic bridges.

All of our solutions can be applied at any point in the bridge's life span to inform maintenance strategies, ensure public safety and demonstrate due diligence on the part of asset owners and operators.

You can find out more in the mini case studies below, or contact us for bespoke advice on our full range of structural investigation and monitoring solutions.

Silver Jubilee Bridge, Newcastle HLB (CS7)

Hidden defect: Suspension bridge hangers

Problem: The client wanted to conduct load measurement testing on the bridge’s suspension hangers.

Solution: A programme of load measurement on the hangers of the bridge was undertaken using vibration measurement techniques in order to accurately confirm the dead load condition.

Newcastle High Level Bridge

Hidden defect: Compression members

Problem: The client required data relating to the load upon cast iron compression members / wrought iron (hidden) hangers.

Solution: JF Strainstall was employed to monitor the loads within cast iron compression members and wrought iron (hidden) hangers before and during hanger replacement. The purpose was to ensure that load redistribution during hanger removal was managed safely and then to ensure that new hangers were tensioned to the correct level.

Albert Edward Bridge

Hidden defect: Brittle fracture

Problem: Cracked cast iron spandrel posts.

Solution: JF Strainstall set up a system to monitor a cracked cast iron arch bridge in order to determine whether the structure was further deteriorating. Cracks existed at the top and bottom of integral spandrel posts and the problem was originally managed by frequent roped access inspection. The monitoring regime substantially reduced the inspection frequency and has provided a cost-effective method for managing the problem for over 11 years.

Comberford Hall Bridge

Hidden defect: Bolting and rivets

Problem: The effectiveness of riveted flange plates was called into question following an assessment of the bridge structure.

Solution: The effectiveness of riveted flange plates on a multi-span through girder rail bridge was monitored by JF Strainstall. According to assessment codes, the lap length where plates were built up to resist bending moments was insufficient, resulting in the bridge failing its assessment. The monitoring project established that there was hidden strength and the assessment could be amended.

M6 Bescot and M5 Oldbury Viaducts (CS4)

Hidden defect: Internal box sections

Problem: Concerns were raised regarding the condition of welded box sections on the bridge structure and their susceptibility to fatigue damage.

Solution: JF Strainstall designed and installed unattended dynamic monitoring systems to measure the strain under live traffic loading over a one month period at each site. Each location was fitted with 150 gauges and the data collected was used to calculate the fatigue life consumption at both locations.

Trowse Bridge and Caerphilly Station

Hidden defect: Deck plates, jack arches

Problem: The degree of load transfer from the deck plates to longitudinal beams was unknown, causing assessment calculations to call for a weight limit to be imposed on the bridge.

Solution: JF Strainstall completed controlled static load testing. The use of known weights combined with the measurement of displacement and strain enabled more accurate assessments to take place at the site.

Forth Road Bridge

Hidden defect: Fatigue cracking

Problem: During a routine inspection, damage to the bridge was noted. This included the complete fracture of one element of the truss end link on the mains span section of the eastern leg of the north tower of the bridge, and the partial fracture of its counterpart. The bridge was closed whilst repairs were carried out.

Solution: JF Strainstall deployed a comprehensive health monitoring system to the bridge, including more than 200 strain gauges, temperature and tilt sensors to measure stress in the bridge members. This monitoring enabled the identification of the root cause of the link failure; a seized pin, and a phased repair was implemented as a result of the findings.

M48 Severn Bridge

Hidden defect: Suspension bridge cables

Problem: The client wanted to conduct strain measurement testing on the main suspension cables.

Solution: JF Strainstall undertook strain measurement testing under live load conditions, conducting measurements on the wires within the main cables.

Read article

Read article

Detection of bridge impact

Read article

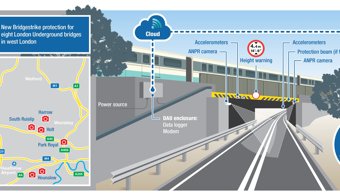

Bridgestrike installed two key bridges London underground

Read article

JF Strainstall delivers structural health monitoring project three Normandy bridges

Read article

JF Strainstall commissions structural health monitoring solution Queensferry crossing

Read article

Queensferry crossing meets internet things new bridge new rules

Read article

Bridge load testing eco city, Kuala Lumpur

Read article

Hidden bridge defects | Sub structure solutions

Read article