James Fisher Strainstall, a part of James Fisher and Sons plc group, is a broad-based engineering firm that specialises in load measurement and sensor based safety technology.

Established in 1965 James Fisher Strainstall (JF Strainstall) has developed more than 45 years’ experience in the manufacturing of standard and bespoke load cells. It also assists industries through operations by ensuring structures, equipment and infrastructure are safe to use. The Managing Director of Strainstall, Simon Everett, commented on the developments saying:

Simon EverettManaging Director of StrainstallToday JF Strainstall has over 140 employees around the globe, in locations such as the UK, Dubai, Singapore and Australia. We provide solutions for load measurement and monitoring operations across a wide range of industries, but are particularly focused on the oil and gas market.

With a focus on technology and engineering expertise, JF Strainstall has mechanical, electrical, electronic and software engineering capabilities available in-house to consistently develop new products and technology.

Simon EverettEngineers make up approximately a third of the headcount of our company and our in-house capabilities give us the opportunity to bring multi-discipline teams together to produce integrated solutions. We emphasise the importance of reliability and have developed specific technologies for use in harsh environments and subsea. We can also provide solutions where our competitors can’t due to our extensive hazardous area expertise.

Working with a diverse range of customers across a variety of market sectors, ranging from oil majors, EPCs, service companies and lifting equipment firms, JF Strainstall is proud of its ability to find solutions to even the most complex of demands due to its dedication to customer service and expansive knowledge in load monitoring and environmental applications.

Simon EverettTo solve the problems of our customers it is imperative we work closely with them, in many cases we have become the technology partners to a growing list of key clients who use us as an extension of their own teams, thus making us an integrated part of their solution.

The world's leading supplier of load monitoring solutions

Load monitoring has always been at the centre of JF Strainstall’s activities, but there has been increasing interest in the oil and gas sector. Using its offshore and marine experience, the company provides integrated management solutions from its range of information and control outputs. A recent product developed by JF Strainstall is the Vessel Motion Monitoring System (VMMS), which monitors transfer boat movements. Its primary function is to enable the safe transfer of personnel from vessel to vessel/structure; it can also provide a more comprehensive monitoring system and has widespread applications from operations in the offshore oil and gas industry to the offshore wind turbine industry.

Shell Prelude - the world’s first floating liquefied natural gas (FLNG) project:

Another state-of-the-art product that JF Strainstall is due to deliver is its quick release mooring hook (QRMH) system for the Shell Prelude project, the world’s first floating liquefied natural gas (FLNG) project.

Simon EverettAlong with our colleagues in Fendercare Marine, we have worked with Samsung Heavy Industries (SHI) to develop QRMHs specifically suited for this demanding offshore application. We believe this is the first time QRMHs have been developed for green seas conditions and are proud to support SHI and Shell on this prestigious project.

The FLNG will be deployed at Shell’s Prelude gas field, 120 miles offshore Western Australia, where it will be permanently moored for approximately 25 years. JF Strainstall will supply the vessel’s QRMH systems and an instrumentation package to provide the safe and quick mooring of LNGs to the FLNG. The mooring loads will also be monitored by the firm in real-time by strain gauged load pins that have been incorporated into the QRMHs, enabling each mooring line to be pre-tensioned to satisfactory load values as well as providing data to protect line performance. Digital signals from the hook sensors are transmitted to the FLNG control room, where mooring line tension is displayed and visual and audible alarms are provided in the event of under/overloads. Furthermore, the QRHs are fitted with remote release to enable an emergency release from the control room.

This project follows JF Strainstall joining forces with sister company Fendercare Marine, also part of the James Fisher group of companies, in 2012. It is a mutually beneficial partnership that further enhances both companies’ prospects to develop a stronger foothold in the oil and gas industry.

Simon EverettWe have a great opportunity to grow the business over the next five years and beyond. Becoming part of Fendercare Marine enables us to extend our global reach and bring our combined expertise for the benefit of our customers, as has been demonstrated on the Shell Prelude project.

Following this project with Shell and future expectations of growth in the LNG market, JF Strainstall has invested in a 10,000 square foot facility dedicated to the production of jetty systems.

Over the coming years JF Strainstall aims to continue improving the solutions it can offer customers by investing in new product research and development, which will enhance opportunities for international growth.

Simon EverettWe have expanded our engineering and project management, and engineering teams and will continue to do so in order to deliver increasing numbers of tailored solutions. With a foundation of engineering excellence and the ongoing oil and gas industry boom we believe the prospects for JF Strainstall are excellent.

Read article

Read article

Detection of bridge impact

Read article

Monitoring Railway for Washout

Read article

Monitoring railway bridge for flood warning

Read article

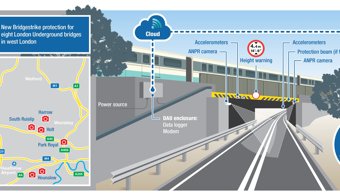

Bridgestrike installed two key bridges London underground

Read article

Channel tunnel investigation undertaken by James Fisher Strainstall

Read article

JF Strainstall delivers structural health monitoring project three Normandy bridges

Read article

JF Strainstall commissions structural health monitoring solution Queensferry crossing

Read article