Structural Health Monitoring (SHM) is increasingly important for bridge asset management. The objectives are a mix of risk and safety management, improved maintenance scheduling, and the measurement of ongoing deterioration.

James Fisher Strainstall (JF Strainstall) understands bridges. We know how to deploy monitoring technologies to help bridge owners and operators to manage them more efficiently. Since the late 1990s, we have monitored or load tested over 600 bridges of all types and sizes.

We are agnostic to sensor type and suppliers: we use the appropriate monitoring technology for each specific application, with our ability to integrate data from any source within our SAMS™ software platform being key to our independent approach.

SHM is commonly required for new bridges:

- To provide real-time alerts for unplanned events. These include weather-related incidents (high wind, extreme temperature), earthquakes, overloaded vehicles or impacts from vehicles/ships.

- To record utilisation of key elements, (eg bearings, expansion joints) so that replacement/ intervention can be planned based on the asset’s specific requirements.

- To monitor aspects that have been problematic in earlier bridge designs, for instance steel deck fatigue or foundation settlement

- To provide long-term bridge performance information. For example, this helps to understand whether a bridge is behaving as designed and whether it will continue to do so.

SHM for existing bridges is usually required in response to a known or suspected problem:

- Actual defects: When defects are found during inspections, such as cracking or evidence of bearing faults

- Vulnerable details: When vulnerable details are suspected in cases where the condition is not easy to check through inspections, for instance the deterioration of post-tensioned concrete structures or concrete half joints, or other hidden defects

- Load carrying capacity: When a bridge fails its numerical assessment

It can also be used as a cost-effective and safer alternative to ongoing periodic manual monitoring of certain defects, with the added benefit of providing a full and consistent data record.

JF Strainstall is independent of equipment manufacturers. Our skill is in knowing which technology to use for each application.

Typical measurements include displacement, deflection, strain, acceleration (vibration), inclination (tilt), settlement, temperature, weather (wind speed, wind direction, pressure, relative humidity, rainfall, sunshine, visibility).

JF Strainstall also deploys third party systems (GNSS, Automatic Total Station, RC Corrosion, Dynamic Weigh-in-Motion, Acoustic Emission Monitoring) and integrates the data in its SAMS™ platform, so that users have one interface to be able to access all data from multiple monitoring hardware systems and even across multiple bridges. All analysis and reports are produced and accessed from the same interface.

JF Strainstall has brought many innovations to the bridge monitoring world, including sensor technologies and data management and visualisation. The latest involves an InnovateUK funded research project (with partners), ‘SmartBridge’, a digital twin combining finite element analysis and deterioration models with SHM.

Monitoring Systems

James Fisher Strainstall is independent of equipment manufacturers. Our skill is in knowing which technology to use for each application.

Typical measurements include displacement, deflection, strain, acceleration (vibration), inclination (tilt), settlement, temperature, weather (wind speed, wind direction, pressure, relative humidity, rainfall, sunshine, visibility).

JFS also deploys third party systems (GNSS, Automatic Total Station, RC Corrosion, Dynamic Weigh-in-Motion, Acoustic Emission Monitoring) and integrates the data in its SAMS™ platform, so that users have one interface to be able to access all data from multiple monitoring hardware systems and even across multiple bridges. All analysis and reports are produced and accessed from the same interface.

Download our bridge health structural monitoring brochures

If you are making an enquiry about a product or service, please use our sales enquiry form.

Read our latest news

James Fisher Strainstall provides structural health monitoring system for the world’s tallest railway bridge

Read article

James Fisher Strainstall secures Places of Westminster instrumentation and monitoring contract

Read article

All Monitoring Data in One Platform

Read article

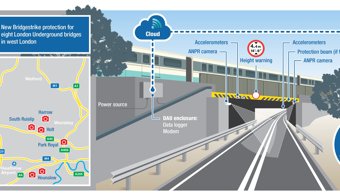

Detection of bridge impact

Read article

Bridgestrike installed two key bridges London underground

Read article

JF Strainstall delivers structural health monitoring project three Normandy bridges

Read article

JF Strainstall commissions structural health monitoring solution Queensferry crossing

Read article

Queensferry crossing meets internet things new bridge new rules

Read article