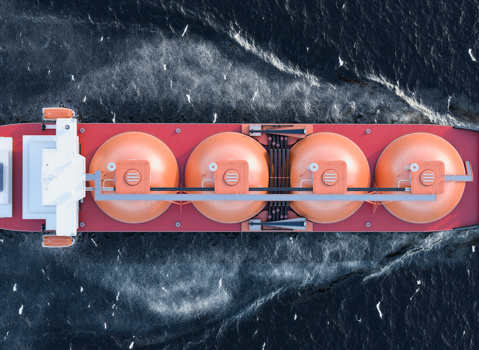

James Fisher Strainstall (JF Strainstall) is a world leader in the development of innovative monitoring solutions to enhance the safety and performance of your assets.

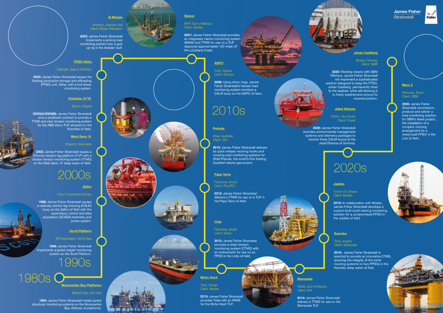

Drawing on more than 50 years’ experience, we develop and apply our innovative technology, including load, strain and stress measuring techniques, within a wide range of sectors including marine, offshore, civil engineering, rail and aerospace.

In 2016 JF Strainstall celebrated 50 years at the forefront of developing innovative monitoring solutions for its customers

We specialise in the design and manufacture of standard and bespoke load cells, strain gauges and integrated systems which are proven to perform year on year in hostile and hazardous environments.

Whether a project is large or small, we provide a range of services including hull stress monitoring, crane weighing and overload, tendon and riser tension monitoring in TLPs.

Our instrumentation and software systems capture and analyse data on parameters such as strain, displacement, inclination, temperature, vibration and water levels to provide asset owners and operators with a comprehensive and real-time overview of events to realise optimum performance.

JF Strainstall has been part of James Fisher and Sons plc since 2006. James Fisher is a leading provider of specialist services to the marine, oil and gas and other high assurance industries worldwide.

If you are making an enquiry about a product or service, please use our sales enquiry form.

Read our latest news

Read article

Read article

Sale of Mimic and Strainstall

Read article

James Fisher Strainstall provides structural health monitoring system for the world’s tallest railway bridge

Read article

James Fisher Strainstall secures Places of Westminster instrumentation and monitoring contract

Read article

James Fisher combines its asset monitoring capabilities under the new brand of James Fisher Strainstall

Read article

All Monitoring Data in One Platform

Read article

Detection of bridge impact

Read article

Monitoring Railway for Washout

Read article