Company history

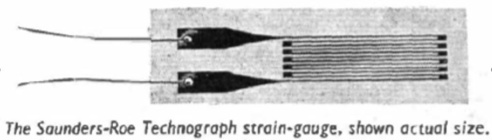

1952

The bonded foil strain gauge was invented at Saunders Roe on the Isle on Wight by Peter Scott-Jackson. Peter was a member of Saunders Roe's Strain Gauge Division where he was joined by Chief Engineer and Founder of JF Strainstall Frank Hartshorne.

1966

Keen to further commercialise the technology, Frank Hartshorne, Bob Eldridge, and Archie Court founded Strainstall in Cowes, Isle of Wight. It was here that the company would pioneer the use of bonded foil strain gauge in load cells for high-assurance industries worldwide.

1967

JF Strainstall designs and installs structural monitoring equipment on the first UK nuclear power station to use a pre-stressed concrete pressure vessel at Oldbury.

1973

JF Strainstall develops the first intrinsically safe hazardous area strain gauge amplifier to meet the safety demands of oil and gas operations in the North Sea.

1982

JF Strainstall supplies hazardous area load monitoring equipment for the UK’s National Coal Board. The equipment is specifically designed to operate safely in the potentially explosive and dusty atmosphere of coal mines. To this day, the company continues to supply specialised load cells for long wall mining applications.

1987

JF Strainstall’s load cells support Richard Branson as he flies across the Atlantic in a hot air balloon.

1988

JF Strainstall delivers load monitoring technology for the world’s largest ship lifting system at Devonshire Dock Hall, helping to safely lift Trident submarines.

1991

JF Strainstall develops its patented strain ring surface strain measurement device. The strain ring was initially developed for a Ministry of Defence contract to monitor load and fatigue damage in rapid deployable military bridges.

1994

JF Strainstall launches its StressAlert Hull Stress Monitoring System (HSMS). The system has been continually developed and updated over the years and has been installed on over 300 vessels since its launch.

1996

JF Strainstall first deploys its strain rings in offshore upstream operations. Since then, this technology has been widely used in the oil and gas sector.

1998

We commenced dynamic testing of 100 rail bridges for the West Coast Mainline upgrade for faster, tilting trains.

2002

JF Strainstall is awarded a landmark contract for the Abb Vetco tension leg platform in Exxon’s Kizomba oil field – off the coast of Angola.

2005

We installed our structural monitoring system for the world's tallest tower, the Burj Khalifa in Dubai.

2006

James Fisher and Sons plc (JFS) acquires JF Strainstall. This combines JF Strainstall’s specialist load monitoring experience with JFS’s global capability and depth of expertise.

2010

JF Strainstall installed an advanced structural monitoring and data management solution for a major fixed-bottom offshore wind farm in Europe. Since then, the company has been contracted to install its structural monitoring system for over 170 assets in the global offshore wind sector

2015

JF Strainstall launch its Container Weight System (CWS), which was quickly adopted by ports around the world to answer the industry’s SOLAS safety regulations.

2019

JF Strainstall continues to drive the renewables sector’s sustainable development by supplying load monitoring equipment to support the world's largest floating offshore wind farm.

Coming soon

JF Strainstall has a host of exciting new technologies and projects in the pipeline.

If you are making an enquiry about a product or service, please use our sales enquiry form.

Read our latest news

Read article

Read article

Sale of Mimic and Strainstall

Read article

James Fisher Strainstall provides structural health monitoring system for the world’s tallest railway bridge

Read article

James Fisher Strainstall secures Places of Westminster instrumentation and monitoring contract

Read article

James Fisher combines its asset monitoring capabilities under the new brand of James Fisher Strainstall

Read article

All Monitoring Data in One Platform

Read article

Detection of bridge impact

Read article

Monitoring Railway for Washout

Read article