James Fisher Strainstall (JF Strainstall) has a number of specialist solutions for structures and investigation methods.

We specialise in the implementation of special inspections for highway and rail bridges including:

- Special visual inspections

- Measurement of as-built details

- Detailed investigation of current conditions

- Use of traditional non-destructive testing techniques (MPI, eddy current, ultrasonics, radiography)

- Advanced ultrasonics (phased array ultrasonics, long-range, automated and robotic investigation, total focusing method)

- Use of unmanned aerial vehicles (UAVs) for visual and ultrasonic investigations

- Short-duration monitoring and load tests

We can provide asset owners with extensive condition investigations and guidance by using several infrastructure asset management services, together with extensive experience from a team that includes chartered civil engineers. Our services range from desk studies to complex data analytics and can include many varieties of inspection and testing. We are bringing together the breadth of technologies and experience within the James Fisher group to provide comprehensive asset condition information and interpretation.

Our capabilities

- Advise on asset management risks and prioritisation

- Offer an overview of techniques available

- Guide appropriate measures for specific scenarios

- Conduct combined investigations to give complete condition information

- Provide monitoring for future changes

- Factual and interpretive reporting

Read more about our capabilities below

James Fisher Strainstall (JF Strainstall) can provide comprehensive bridge bearing condition investigation and offer data-driven analysis on the remaining life of the bearings.

Bridge bearings are known to deteriorate due to corrosion, debris and wear. Leading to resistance, and numerous other potential future problems. Knowing their condition can provide tell-tale signs of other effects to the bridge and allow future planning for maintenance.

We offer impartial advice through inspection, non-destructive testing and dynamic monitoring. We will review the performance of each bearing individually and collectively, as they respond to a number of investigations.

JF Strainstall offers a range of inspection, investigation and monitoring services, including:

- Detailed visual inspection of bearings

- Inspection of expansion joints, structural components and other influencing parts

- Measurement of bearing displacement offset, mapped throughout the bridge to compare thermal displacement at a point in time

- Ultrasonic investigation for cracking or corrosion

- Investigation of bolts including detection of defects hidden inside joints or concrete

- High-speed monitoring of bearing movements, displaying a response to temperature variation and vehicle loads

- Interpretive review for bearing condition and its effects on the structure

- Recommendations for the longevity of remaining life, maintenance needed or replacement programme

JF Strainstall provides consultation and comprehensive post-tensioned concrete bridge special inspections (PTSI). We can examine details, inspect and conduct condition investigations to avoid unnecessary intrusive investigations.

Post-tensioning for concrete structures can vary between simply threaded bars to complex multi-strand arrangements in decks, beams, crossheads or piers. Particularly onerous features include segmental constructions or tensioning at inaccessible locations. Notable failures at Ynys-y-Gwas (1985) and more recently in Genoa (2018) have highlighted the vulnerability of post-tensioned bridges to hidden defects.

Ongoing investigations and monitoring schemes are crucial to avoid any repeat occurrences. However, DMRB DB54/15 requires all post-tensioned concrete structures to be managed on a risk basis and conduct investigations where necessary.

James Fisher Strainstall (JF Strainstall) can provide condition investigation services for bridges with reinforced concrete half-joints. From the initial consultation through to risk review and testing, JF Strainstall seeks to determine the likelihood of serious defects and advise on the structural performance.

Half-joints in reinforced concrete bridge decks and sub-structures are found in a variety of forms, which are often in difficult to inspect places and pose the risk of hidden defects. Common defects start from water leakage through the movement joint, causing corrosion which may go undetected. Visual inspection can find external defects, however, these inspections are frequently insufficient to confirm the internal condition.

In recent years, notable bridge collapses in Canada and Italy have both involved defects at reinforced concrete half joints in which inspection alone was unable to determine the severity of the prior condition.

JF Strainstall offers a comprehensive service including relevant non-destructive techniques for investigation of internal cracking and corrosion. We can also monitor movements and create warning systems for further deterioration along with the services below:

- Review of available drawings, inspections and past investigations

- Special visual inspections

- Risk scoring and prioritisation

- Radar and eddy current scanning to determine internal reinforcement details, checking bar positioning and anchorage lengths

- Concrete condition investigations for external faces, including carbonation, chlorination and half-cell potential

- Ultrasonic screening through concrete for detection of internal cracking at mid-depth

- Structural monitoring for future condition changes and damage detection

- Interpretive review and recommendations for bridge management

JF Strainstall can provide inspection and monitoring techniques for fatigue in metallic structures, as well as the monitoring of strains to predict future fatigue.

By measuring crack development, measuring stress cycles and counting fatigue damage accumulation, we can monitor remotely for progressions and suggest timescales for intervention.

Fatigue cracks developing in steel bridges are often influenced by localised stress, as well as heat affected zones of welded components. Visual inspection rarely finds the minute cracking, which often develops in areas which are hard to access such as box girders or steel decks making early detection difficult.

Traditional testing regimes typically require magnetic particle inspection (MPI) to a proportion of weld details suspected at higher risk. JF Strainstall can offer alternative techniques for defect detection, which avoid surface preparation and the associated hazards. These techniques are safer, quicker and avoid environmental contamination; some techniques can even be conducted remotely.

JF Strainstall can also provide services including:

- Review of available drawings, to comment on stress concentration prone details and fatigue risk

- Strain monitoring

- Fatigue damage calculation and graphical display on SAMS™

- Weld visual inspections for construction quality

- Eddy current testing verified locally by MPI or dye penetration

- ACFM for comprehensive investigation and crack depth measurement, without paint removal

- Robotic corrosion mapping

- Phased array ultrasonic weld inspection

Collisions to bridges by vehicles cause disruptions and require a swift response to ensure that public safety is maintained and there is minimal road disruption. Damage by floating debris in flood events can be equally damaging and demand similar attention.

For concrete bridges, this can involve hammer tap survey or ultrasonic investigation for crack mapping. For steel or iron structures we recommend ACFM (alternating current field measurement), in which eddy currents are used to measure extents and depth of cracks and laminations without removing paint. Many other techniques are also available and their relevance can be assessed for the specific conditions.

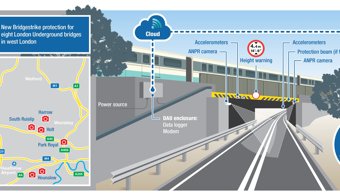

JF Strainstall also has a range of monitoring solutions, known as BridgeStrike, which constantly check in real time the bridge deck for sudden movements that suggest an impact. Our cameras can record images of the vehicle before, during and after impact, which assists with bridge management as well as perpetrator prosecution.

Other monitoring options from JF Strainstall can detect over-height, over-width and/or over-weight vehicles, which then activate warning signs pre-empting and avoiding impact. We can detect even fine over-height aerials which could conflict with electrified railway overhead line equipment (OLE).

Other services available:

- Review of previous impact damage and testing conducted

- Emergency visual inspections

- Dimension surveys for assessment

- Broad range of non-destructive testing including ultrasonic and ACFM

- Review of impact severity and recommendations

- BridgeStrike monitoring for impact records and imagery

- Impact magnitude recording for future enhanced response

- Over-height, over-width and over-weight vehicle detection to activate warning signs

James Fisher Strainstall (JF Strainstall) has a number of specialist solutions for structures and investigation methods.

We specialise in the implementation of special inspections for highway and rail bridges including:

Special visual inspections

- Measurement of as-built details

- Detailed investigation of current conditions

- Use of traditional non-destructive testing techniques (MPI, eddy current, ultrasonics, radiography)

- Advanced ultrasonics (phased array ultrasonics, long-range, automated and robotic investigation, total focusing method)

- Use of unmanned aerial vehicles (UAVs) for visual and ultrasonic investigations

- Short-duration monitoring and load tests

We can provide asset owners with extensive condition investigations and guidance by using several infrastructure asset management services, together with extensive experience from a team that includes chartered civil engineers. Our services range from desk studies to complex data analytics and can include many varieties of inspection and testing. We are bringing together the breadth of technologies and experience within the James Fisher group to provide comprehensive asset condition information and interpretation.

Our capabilities

- Advise on asset management risks and prioritisation

- Offer an overview of techniques available

- Guide appropriate measures for specific scenarios

- Conduct combined investigations to give complete condition information

- Provide monitoring for future changes

- Factual and interpretive reporting

Deterioration can occur inside the closed hollow sections and fastening bolts of bridge parapets, due to them often receiving little maintenance after installation. Visual inspection is insufficient to determine the integrity of these hidden features.

JF Strainstall offer a comprehensive service for condition investigation on bridge parapets and highway safety fences using several different services.

Though parapets are included in bridge inspections, the detection of their corrosion is incomplete by visual inspection alone. We recommend cursory checks using non-destructive tests at a sample of locations and periodic intervals. Where there are specific concerns of deterioration, more thorough investigation programmes might be appropriate. We can advise on the appropriate extents of testing suitable.

In some instances, vehicles have collided with parapets when attempting to access bridges with height or width restrictions. Undetected defects caused by these collisions lead to bridge parapets not meeting the intended rated resistance. Highways England provides advice on management of parapets, including risk ranking and prioritising upgrades.

JF Strainstall can, using the breadth of our specialist teams, provide services including:

Collating and review of record information

- Visual inspection

- Ultrasonic thickness measurements for posts and rails – for which we suggest B-scans to establish both minimum and average thickness

- Bolt scanning by phased array ultrasonic testing

- Weld inspection and testing

- Bolt load testing and certification

- Paint inspection and testing

- Inspection and measurements at zones of impact and use of

- ACFM technique for damage measurements

- Physical load testing of barrier system (static or dynamic)

- Monitoring for changes in condition or safety fence tension

- Since parapet resistance is reliant on the supporting structural plinth, we can extend investigations into the steel or concrete components around

- Risk rating and recommendations for management programme

Load testing provides vital information about a structure’s response to applied loadings. Controlled loading is applied statically or dynamically within safe limits, enabling serviceability and ultimate load capacities to be calculated.

We understand structures. We have extensive experience in the assessment of structures and we know how to help if calculations suggest there is insufficient capacity. We can carry out:

- Design verification testing for new structures

- Supplementary testing for existing structures

- Proof load testing

- Since the late 1990s, we have monitored or load tested over 600 bridges. In each case, we are able to advise on the best approach, to arrange and manage the test load, to set up and operate the instrumentation, and to analyse and report on the findings.

New bridges

Load testing generates structural response data under controlled conditions, which can be compared with design expectations. The data can be used to refine influence lines and, where fitted, to check that permanent structural health monitoring systems are performing adequately.

Load application generally uses loaded, pre-weighed vehicles. These can be stopped at specific locations for static measurements to be taken. Additionally, or alternatively, the vehicles can be driven across the bridge in controlled formation at constant speed – with their location being monitored. While dynamic responses are measured directly, pseudo-static responses can be accurately inferred.

The key measurement parameters normally required are the global displacement and vibration responses, which can be obtained in a variety of ways. These methods include: GNSS, total station, video gauge, physical displacement sensors, tilt sensors, accelerometers and strain gauges.

Existing bridges

Supplementary load testing is used to help improve the accuracy of numerical assessment. Response measurements are generally displacement and strain, focused on the structural elements or details where the assessed capacity is deemed sub-standard. The applied load is carefully selected to mobilise an elastic response, without causing damage. This loading can be by road vehicles, jacks, kentledge, people or, in the case of rail bridges, normal passing trains.

Proof load testing can also be undertaken: This involves the application of the maximum load required to use the structure to demonstrate that it is strong enough. There is a risk of irrecoverable damage to the structure and this method is not often used. We have established methods of controlling load cycles to ensure that the risk of damage is minimised and defects are detected early.

The terminology load test is usually used in the context of live loading. However, in bridge assessment, the assumptions made about the dead load stress condition – notably with post-tensioned concrete – can have a significant impact on the capacity that remains available for live loads. We provide a suite of complementary tests for the measurement of the dead load stresses, enabling further refinement of the assessment. Find out more about residual stress testing.

Buildings

Alterations to buildings, for example the construction of atriums, the installation of shafts or stairwells, and the removal of walls, will all influence their structural integrity. Deflections under load must be within limits in order to comply with serviceability requirements.

We provide a comprehensive service to design and carry out floor slab deflection testing, which typically utilises water-filled bags to apply load, with displacement sensors and data-loggers to monitor the responses. Local tests and point loads can be created and finely controlled with kentledge and jacking.

Other structures

We also undertake load testing of crowd control barriers in sports stadiums, theatres, and art installations. These require the use of jacks to apply the appropriate controlled loads. Find out more about assurance and compliance testing

Read article

Read article

All Monitoring Data in One Platform

Read article

Detection of bridge impact

Read article

Bridgestrike installed two key bridges London underground

Read article

JF Strainstall delivers structural health monitoring project three Normandy bridges

Read article

JF Strainstall commissions structural health monitoring solution Queensferry crossing

Read article

Queensferry crossing meets internet things new bridge new rules

Read article

Bridge load testing eco city, Kuala Lumpur

Read article