Load testing provides vital information about a structure’s response to applied loadings. Controlled loading is applied statically or dynamically within safe limits, enabling serviceability and ultimate load capacities to be calculated.

We understand structures. We have extensive experience in the assessment of structures and we know how to help if calculations suggest there is insufficient capacity. We can carry out:

- Design verification testing for new structures

- Supplementary testing for existing structures

- Proof load testing

Since the late 1990s, we have monitored or load tested over 600 bridges. In each case, we are able to advise on the best approach, to arrange and manage the test load, to set up and operate the instrumentation, and to analyse and report on the findings.

New bridges

Load testing generates structural response data under controlled conditions, which can be compared with design expectations. The data can be used to refine influence lines and, where fitted, to check that permanent structural health monitoring systems are performing adequately.

Load application generally uses loaded, pre-weighed vehicles. These can be stopped at specific locations for static measurements to be taken. Additionally, or alternatively, the vehicles can be driven across the bridge in controlled formation at constant speed – with their location being monitored. While dynamic responses are measured directly, pseudo-static responses can be accurately inferred.

The key measurement parameters normally required are the global displacement and vibration responses, which can be obtained in a variety of ways. These methods include: GNSS, total station, video gauge, physical displacement sensors, tilt sensors, accelerometers and strain gauges.

Existing bridges

Supplementary load testing is used to help improve the accuracy of numerical assessment. Response measurements are generally displacement and strain, focused on the structural elements or details where the assessed capacity is deemed sub-standard. The applied load is carefully selected to mobilise an elastic response, without causing damage. This loading can be by road vehicles, jacks, kentledge, people or, in the case of rail bridges, normal passing trains.

Proof load testing can also be undertaken: This involves the application of the maximum load required to use the structure to demonstrate that it is strong enough. There is a risk of irrecoverable damage to the structure and this method is not often used. We have established methods of controlling load cycles to ensure that the risk of damage is minimised and defects are detected early.

The terminology load test is usually used in the context of live loading. However, in bridge assessment, the assumptions made about the dead load stress condition – notably with post-tensioned concrete – can have a significant impact on the capacity that remains available for live loads. We provide a suite of complementary tests for the measurement of the dead load stresses, enabling further refinement of the assessment. Find out more about residual stress testing.

Buildings

Alterations to buildings, for example the construction of atriums, the installation of shafts or stairwells, and the removal of walls, will all influence their structural integrity. Deflections under load must be within limits in order to comply with serviceability requirements.

We provide a comprehensive service to design and carry out floor slab deflection testing, which typically utilises water-filled bags to apply load, with displacement sensors and data-loggers to monitor the responses. Local tests and point loads can be created and finely controlled with kentledge and jacking.

Other structures

We also undertake load testing of crowd control barriers in sports stadiums, theatres, and art installations. These require the use of jacks to apply the appropriate controlled loads. Find out more about assurance and compliance testing.

If you are making an enquiry about a product or service, please use our sales enquiry form.

Read our latest news

Read article

Read article

All Monitoring Data in One Platform

Read article

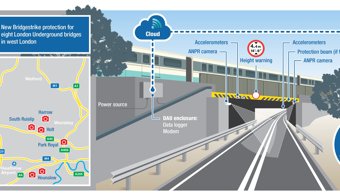

Detection of bridge impact

Read article

Bridgestrike installed two key bridges London underground

Read article

JF Strainstall delivers structural health monitoring project three Normandy bridges

Read article

JF Strainstall commissions structural health monitoring solution Queensferry crossing

Read article

Queensferry crossing meets internet things new bridge new rules

Read article

Bridge load testing eco city, Kuala Lumpur

Read article